**Why Variable-Pitch Bi-Metal Bandsaw Blades Are Better Than Straight Pitch

(And Why Carbon Blades Don’t Come in Variable Pitch)**

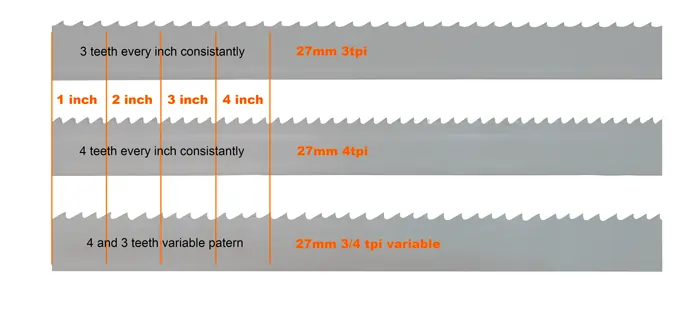

When you’re choosing a narrow bandsaw blade (anywhere from 6 mm to 67mm wide), one of the most important decisions is tooth pitch. Most older-style blades use a straight pitch — the same number of teeth per inch (TPI) repeated across the entire blade.

Modern bi-metal blades, however, are available in something far more effective:

Variable Pitch (VP).

And if you cut metal, stainless, pipe, tube, or structural materials, VP is almost always the better choice.

Below is a simple explanation.

What Is Variable Pitch?

A variable pitch blade alternates between two (or more) tooth sizes, for example:

- 10–14 TPI

- 8–12 TPI

- 6–10 TPI

- 3–4 TPI in the example image above

Instead of every tooth being identical, the pattern repeats in a controlled sequence. Think of it as a blade that constantly changes its “rhythm” as it cuts.

This is not random — the tooth groupings are engineered to break up vibration, stabilise the cut, and increase blade performance.

Straight pitch is something like:

- 14 TPI, 14 TPI, 14 TPI, 14 TPI…

Variable pitch is:

- 10 TPI, 10 TPI, 10 TPI, 12 TPI, 12 TPI,12 TPI, 10 TPI, 10 TPI, repeat…

Why Variable Pitch Is Better

1. Much Lower Vibration = Cleaner, Faster Cuts

Straight pitch blades tend to “harmonise” — they hit the material with identical spacing over and over.

- This causes:

- vibration

- noise

- small ripples in the cut

- blade chatter (especially in tube and RHS)

Variable pitch disrupts this harmonic effect.

The tooth spacing is always slightly different, so the blade doesn’t bounce on the workpiece. - This gives you:

- a quieter cut

- smoother surface finish

- less chatter

- less operator fatigue on smaller machines

2. Longer Blade Life

Because vibration is reduced, tooth tips don’t get hammered in the same spot repeatedly.

Benefits include:

- reduced tooth chipping

- reduced micro-fractures in the cutting edge

- slower wear rate

- longer intervals between blade changes

For most users, VP blades last 30–50% longer than straight pitch in mixed steel work.

3. Handles Mixed Profiles Better (Tube, Pipe, RHS, Channel)

Straight pitch blades struggle when going from:

- thin wall → thick wall

- flat → curves

- solid → hollow

- bar → angle iron

You end up with: - tooth overload

- jarring when the blade “breaks into” the material

- snatched teeth on exit

Variable pitch spreads the load over different teeth, so the cut is more controlled and progressive.

This is especially true on small hobby or light industrial saws with less rigidity.

4. More Versatility on One Blade

A straight 14 TPI blade is only good for thin material.

A straight 6 TPI is only good for thick material.

A 10–14 TPI variable pitch can handle:

- thin wall

- medium wall

- small solids

- pack cutting

A 6–10 TPI can handle:

- solid bar

- medium structural

- mixed steels

- tubes without snagging

For workshops cutting a mix of jobs, VP blades simply out-perform.

5. Designed for Modern Bi-Metal Technology

Variable pitch is engineered specifically for bi-metal M42 and M51 blades.

Bi-metal blades have:

- a flexible alloy steel backer

- a high-speed steel cutting edge (M42)

This design allows variable pitch teeth to be ground and heat-treated accurately. Straight pitch blades still exist, but they do not make use of the advantages of modern metallurgy and tooth design.

Why Carbon Blades Don’t Come in Variable Pitch

Customers often ask: “Why can’t I get a carbon blade in variable pitch?”

Here’s the simple answer:

Carbon blade manufacturing cannot support precise VP tooth grouping.

Carbon blades are:

- punched or milled in straight, repeating tooth patterns

- harder to keep consistent during manufacturing

- limited in heat-treating control compared to M42 tooth tips

To produce variable pitch, each tooth group must be:

- ground

- shaped

- set

- hardened

…in a precise sequence.

This isn’t practical or economical on carbon steel.

Also: carbon doesn’t handle vibration well

Variable pitch is designed to reduce vibration in metal cutting.

Carbon steel teeth are too brittle compared to M42 and would chip under the uneven load of VP cutting. That’s why carbon blades remain straight pitch only.

When Should You Still Use Straight Pitch?

A few cases:

- Wood cutting (variable pitch is not needed)

- Very soft metals like aluminium where cut speed matters more than stability

- Very small tooth sizes (e.g., 24 TPI for thin tube) where VP doesn’t exist

- Budget or hobby use where a carbon blade is “good enough”

But for general steel, stainless, or structural work — especially on smaller saws — VP bi-metal is the clear winner.

Summary

Variable Pitch (VP) Bi-Metal Blades Are Better Because:

- Less vibration

- Smoother finish

- Faster cutting

- Longer blade life

- Better for mixed materials

- Designed for modern metal cutting

Carbon Blades:

- Do not come in VP

- Only available in straight pitch

- Best for wood, plastics, and soft materials

- Not ideal for serious metal cutting

Leave a Reply

You must be logged in to post a comment.