Metal Cutting bandsaw blades

Our metal cutting bandsaw blades are designed for cutting steel, stainless steel, and other ferrous metals across a wide range of applications. Selecting the correct bandsaw blade for metal depends on the material type, section size, and cutting requirements. United Products supplies premium European bi-metal and carbide metal cutting bandsaw blades, custom welded to length and optimised for reliable performance in New Zealand workshops.

If you are primarily cutting steel, view our full range of bandsaw blades for steel.

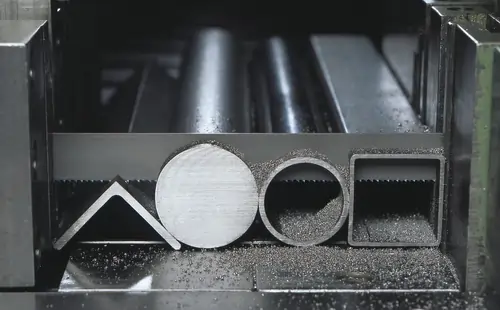

You can cut various types of Metal with everything from a carbon steel hobby blade to a TCT blade.

Some recommended Bandsaw Blade Types for metal cutting

There are many suitable metal band saw- blades to buy depending on your material and size.

Our FAQ contains lots of articles on Choosing TPI and blade type.

If using a Bi-metal blade please don’t forget the break-in

If trying to use a wood bandsaw to cut steel please read Can You Cut Metal on a Wood Bandsaw?

-

Tungsten Carbide Tip Futura SN 27mm x 3/4 tpi

View Product$149.90 Excluding GST Price per metre

To cut Non-ferrous metals

To cut Non-ferrous metals (these are metals that do not contain iron) and softer than Ferrous Metals.

You can use a carbon blade or a hobby blade in a fine tpi. 10 or 14 tpi for thin material down to a few millimeters, or a courser blade (less TPI)for thicker material. Generally any courser than 8 tpi is not recommended. Cutting metals thicker than 10 mm is very hard on the life of carbon blades.

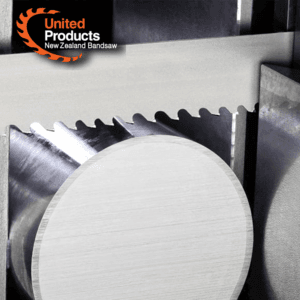

Band sawing Ferrous Metals ( Mild Steel and Harder)

Band sawing Ferrous Metal or Non Ferrous thicker than 10-15 mm works best when using a bi-metal blade and it will be required for any ferrous metals ( mild steel and above) And a TCT ( Tungsten Carbide Tipped) blade for any hardened product

How to select a bandsaw blade for cutting any metal other than Non-ferrous. Ideally you will have a horizontal machine that can run coolant.

Cutting metal is a much more complicated scenario than cutting wood.

Generally home users on vertical Bandsaw designed for wood will have only average success due to 3 main areas of concern

- The machine will run too fast as cutting wood requires higher speeds. Just like on the battery drill you use high speed to drill in to wood and slow it down to drill into steel. The teeth of the saw blade need time to bite into the steel. Or they will just skid across the top and blunting themselves. Horizontal saws designed for steel will have greater speed and feed control to ensure optimum cutting.

- Wood is usually cut at 8-10 times the band saw blade speed compared to cutting steel.

- Heat the high speed will generate heat that will quickly damage the blade.

- Being vertical it is difficult to use coolant without creating a mess. A horizontal metal cutting saw has a spray for coolant and a drip tray to catch filter and recycle it. – Spraying your vertical blade with CRC or WD40 can help but is no solution for heavy cutting.

Here is a rundown on cutting steel with a wood bandsaw Can You Cut Metal on a Wood Bandsaw?

These problems aside, whether or not you have a horizontal metal cutting bandsaw the tpi selection is much more important than when cutting wood and is referenced in several articles below.

before you Buy metal band saw – blades it is suggested you read the following.

Breaking In a Bandsaw Blade: How to Do It Right!

Easy Guide to Selecting Bandsaw Blade TPI (Teeth Per Inch)

Comprehensive Guide to Selecting Bandsaw Blade TPI (Teeth Inch)

There is also good information within these FAQ sections