Frequently Asked Questions

Below the most common FAQ Frequently asked questions are links to more in-depth problem solving particularly for Bi metal blades cutting metal

Why are the bandsaw blade teeth facing the wrong way?

While it may seem that the teeth are on the wrong way, it is simply the band is inside out and needs to be flipped. We weld pre-formed coils of material manufactured in Europe or the USA, we can not put the teeth on the wrong way

to flip the blade follow the instructions here How to flip my bandsaw blade

Choosing the right Meat Bandsaw, What tooth Selection TPI ( Teeth per inch)should I use for Meat?

Nearly all the meat processors, supermarkets and butchers we supply use a 3 tpi blade to cut frozen meat and a 4 tpi blade to cut soft or fresh meat, some use a 6 tpi very occasionally for delicate things like Frenching chops. As the number of teeth increases, the cut becomes finer with less score marks on the meat. However, more teeth means slower cutting.

Our meat cutting blades are here Meat Cutting Bandsaw Blades

This Article will help you choose a meat blade with and tpi Choosing the Right Meat Bandsaw Blade in NZ

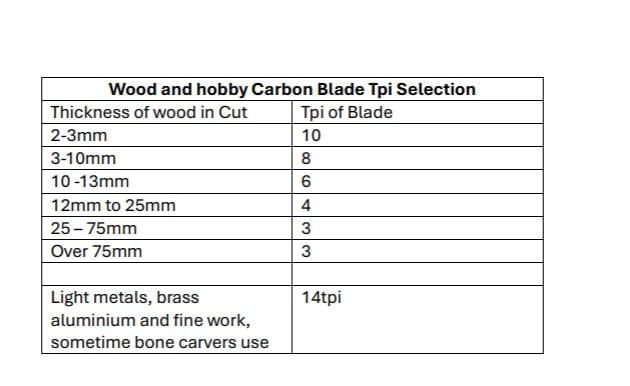

What tooth Selection TPI ( Teeth per inch)should I use for Wood?

When cutting wood there are a few basics to understand

-

- The thickness of the material this will influence the Tpi

As the material get thicker the teeth need to become coarser as the gullet (the gap between the teeth) needs to be wider to be able to take the swarth (sawdust) away. If you think of each tooth as a chisel the longer distance the tooth has to cut though, the more material it will peel off, and this has to go into the gullet, to be carried of the cut, if it cant fit into the gullet because it is too small ( ie. the teeth too fine) it compacts and clogs and holds the tooth tips away from the cutting surface.

At the other extreme if the teeth are too coarse and the material too thin too few teeth are in the material at one time and the load is on a very few teeth, this leads to rough cuts premature tooth wear and possibly teeth stripping off

-

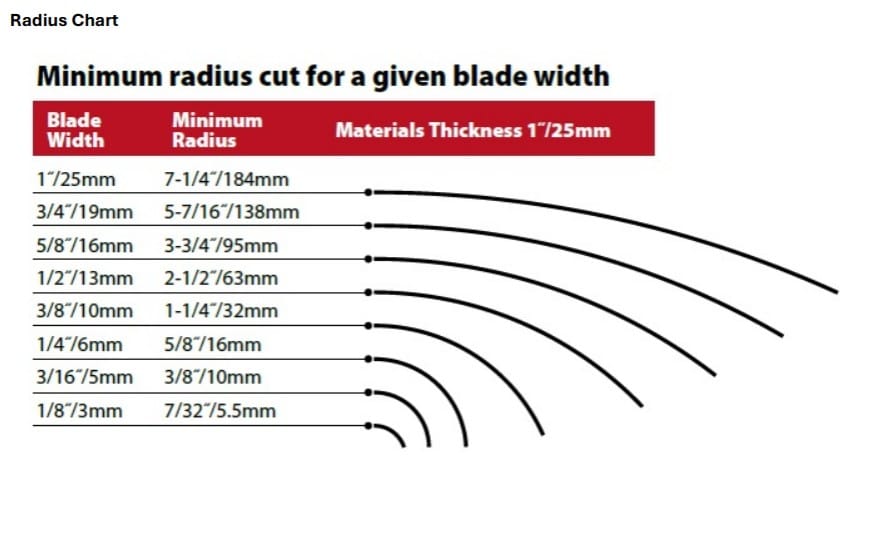

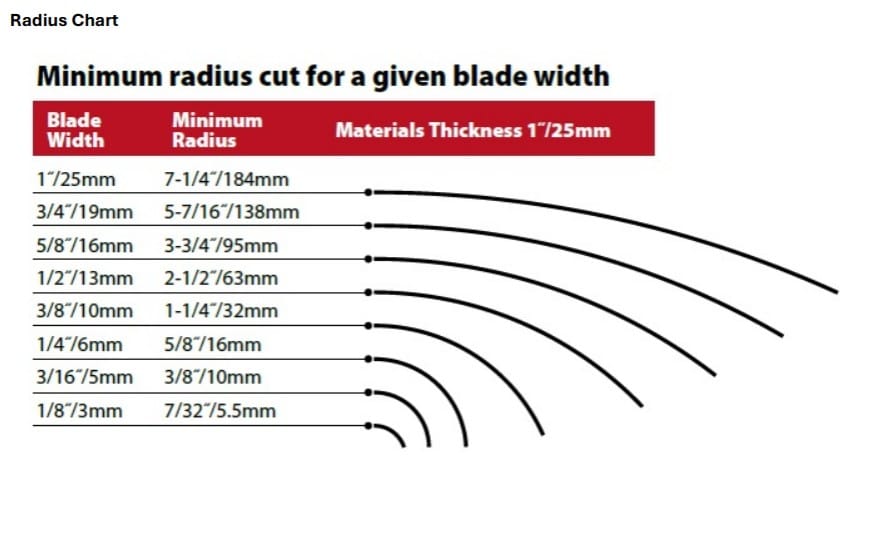

- The nature of the cut straight or curved – this will influence the blade width

Below is a simple wood tpi chart and a radius chart

To cut straight you should always fit the widest blade your saw will take

To cut curves the blade will only turn based on the difference between the cut width and Blade Width

Governed by the blade set ( the teeth bending left and right) to create a cut wider than the band width to stop binding, but as an added bonus allows some twist.

The narrower the blade the more it can twist in the cut width.

What width Blade do I use to cut a curve? – Radius Chart

To cut curves the blade will only turn based on the difference between the cut width and blade width

Governed by the blade set ( the teeth bending left and right) to create a cut wider than the band width to stop binding, but as an added bonus allows some twist.

The narrower the blade the more it can twist in the cut width.

How do I measure my blade length?

There are three different ways to measure the length of a bandsaw blade.

-

- If you do not have a bandsaw blade to look at.

-

- If you have a broken bandsaw blade that you believe is not missing any of its length

-

- If you have a bandsaw blade that is still intact but is just dull or missing teeth

instructions here How to measure your bandsaw blade length

What metal cutting bandsaw blade should I buy?

Choosing a metal cutting bandsaw blade depends on the type of metal, section size, and shape being cut. There is no single blade suitable for all metals. A bi-metal bandsaw blade, often in the 10–14 TPI range, is a common starting point for general metal cutting, but correct tooth selection is critical for blade life and cut quality. Matching the blade type and TPI to the application will deliver far better results than relying on a “one-size-fits-all” blade.

This page here is a great place to start your Metal Cutting Bandsaw Blades research

What tooth Selection TPI ( Teeth per inch)should I use for Metal?

Cutting metal is a much more complicated scenario than cutting wood.

Generally home users on vertical Bandsaw designed for wood will have only average success due to 3 main areas of concern

-

- The machine will run too fast as cutting wood requires higher speeds, just like on the battery drill you use high speed to drill in to wood and slow it down to drill into steel. The teeth of the saw blade need time to bite into the steel or they will just skid across the top and blunting themselves. Horizontal saws designed for steel will have greater speed and feed control to ensure optimum cutting

- Wood is usually cut at 8-10 times the band saw blade speed compared to cutting steel

-

- Heat the high speed will generate heat that will quickly damage the blade

-

- Being vertical it is difficult to use coolant without creating a mess, a horizontal metal cutting saw has a spray for coolant and a drip tray to catch filter and recycle it. – Spraying your vertical blade with CRC or WD40 can help but is no solution for heavy cutting

These problems aside whether or not you have a horizontal metal cutting bandsaw the tpi selection is much more important

here is a link to a chart to help with Choosing a tpi for cutting metal

help to buy metal band saw blades

Can You Cut Metal on a Wood Bandsaw?

It’s a common workshop myth: “If you have a wood bandsaw, you can just swap in a fine blade and cut metal too.”

Technically? Yes.

Practically? You’ll shorten your blade life, risk damaging your saw, and likely end up with a rougher cut than you’d like.

The reasons are outlined in this article and guidance if you want to do it anyway

What are the advantages of using a bimetal bandsaw blade compared to a carbon steel blade?

Bi-metal blades are generally used for cutting steel, bimetal bandsaw blades offer enhanced durability, longer lifespan, better cutting performance, and versatility compared to carbon steel blades. These advantages make them a preferred choice for many cutting applications, particularly in industrial settings where efficiency and precision are crucial.

See “What are the advantages of using a bimetal bandsaw blade compared to a carbon steel blade?” for a more detailed explanation

If you have specific cutting needs or scenarios in mind, feel free to ask for further information!

M42 Bi-Metal Bandsaw Blades: What are they?

What Are Bi-Metal Bandsaw Blades?

Bi-metal bandsaw blades are made by fusing two types of metal:

- High-Speed Steel (HSS): This forms the teeth, providing hardness and resistance to wear.

- Spring Steel Backing: A flexible and durable material that helps the blade resist fatigue.

This dual-metal construction means you get the best of both worlds — cutting performance and durability. They’re a big upgrade from carbon steel blades and ideal for users who want longer life, cleaner cuts, and more efficiency.

Why Choose an M42 Bi-Metal Blade?

M42 refers to a specific grade of high-speed steel that contains 8% cobalt, which boosts its performance. M42 blades are widely regarded as premium options in the bi-metal category. Here’s why:

- High Wear Resistance: M42 blades stay sharper for longer, even in tough applications.

- Handles Tough Materials: Great for alloy steels, stainless steels, structural steels, and hardened metals.

- Heat and Abrasion Resistant: Ideal for high-speed cutting where heat buildup could be a concern.

- M42 Bi-Metal Bandsaw Blades: A Clear Guide for Choosing the Right One

Easy Guide to Selecting Bandsaw Blade TPI (Teeth Per Inch) Part 1

When it comes to choosing the right bandsaw blade, selecting the correct Teeth Per Inch (TPI) is crucial for achieving the best cutting performance. Here’s a simple step-by-step guide to help you make the right choice

Easy Guide to Selecting Bandsaw Blade TPI (Teeth Per Inch):

Selecting the right TPI for your bandsaw blade is essential for achieving optimal cutting results.

By considering the material type, thickness, cutting technique, and desired finish, you’ll be able to make an informed decision that enhances your overall cutting experience.

Comprehensive Guide to Selecting Bandsaw Blade TPI (Teeth Per Inch) Part 2

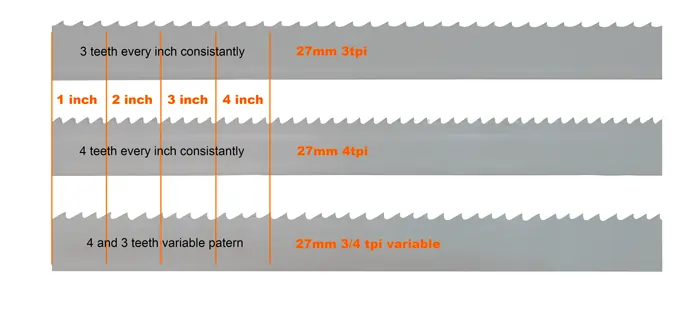

Understanding TPI

- TPI Definition: TPI represents the number of teeth on the blade per inch of length. A higher TPI means more teeth are engaged in the cut, while a lower TPI indicates fewer teeth.Here is the link to the “Comprehensive Guide to Selecting Bandsaw Blade TPI (Teeth Per Inch)“

Why Variable-Pitch Bi-Metal Bandsaw Blades Are Better Than Straight Pitch (And Why Carbon Blades Don’t Come in Variable Pitch)

**Why Variable-Pitch Bi-Metal Bandsaw Blades Are Better Than Straight Pitch

(And Why Carbon Blades Don’t Come in Variable Pitch)**

When you’re choosing a narrow bandsaw blade (anywhere from 6 mm to 67mm wide), one of the most important decisions is tooth pitch. Most older-style blades use a straight pitch — the same number of teeth per inch (TPI) repeated across the entire blade.

Modern bi-metal blades, however, are available in something far more effective:

Variable Pitch (VP).

And if you cut metal, stainless, pipe, tube, or structural materials, VP is almost always the better choice.

Below is a simple explanation.

What Is Variable Pitch?

Why Variable-Pitch Bi-Metal Bandsaw Blades Are Better Than Straight Pitch

What is bandsaw blade break-in? and why do I have to do it?

Bandsaw blade breakin is the conditioning of a new blade to make it ready to run at production levels without premature failure

You don’t have to do it, But every manufacturer globally recommends it as blade life will be extended considerably ( up to 30%)

Read all about how to do it efficiently here in our Breaking In a Bandsaw Blade: Why It Matters and How to Do It Right!

How do I convert Thou to millimeters and visa versa?

the easiest way is to use a chart or google “Thou to millimeters converter” and you will get a converter.

Here is a link to a Thou to millimeters converter chart

For those into Math’s 1 inch = 25.4mm so 0.020 ( twenty thou) = 0.02 x 25.4 = 0.5mm and conversely .63mm = 0.63/25.4 = 0.0248″ ( or 25 thou)

Is a bandsaw blade breaking dangerous?

When a bandsaw is correctly set up and used as intended, blade breakage is rarely dangerous. Modern bandsaws are designed to contain a broken blade, and injuries from blade breakage itself are extremely uncommon.

👉 Read the full explanation:

Are bandsaw blade breaks dangerous?

Are Bandsaw Blade Breaks Dangerous?

What’s the difference between M42 and M51 bandsaw blades?

M51 blades use a higher-alloy high-speed steel tooth material than M42, giving better wear resistance and performance in harder steels and stainless. For workshops that wear through M42 blades quickly, M51-class blades are often the next step.

Follow-on link:

Learn more about how modern M51-class blades work:

👉 M51 vs PM51 Bandsaw Blades: What’s Changed — and Why It Matters

What’s the difference between M51 and PM51 bandsaw blades?

M51 and PM51 are the same grade of high-speed steel. PM51 uses a powder-metallurgy process that produces a finer, more uniform structure, improving resistance to tooth chipping and increasing durability in demanding cutting conditions.

Read the full guide: 👉 M51 vs PM51 Bandsaw Blades: What’s Changed — and Why It Matters

For more in-depth problem solving! or when it isn’t going as expected use these 2 links